2024-02-29

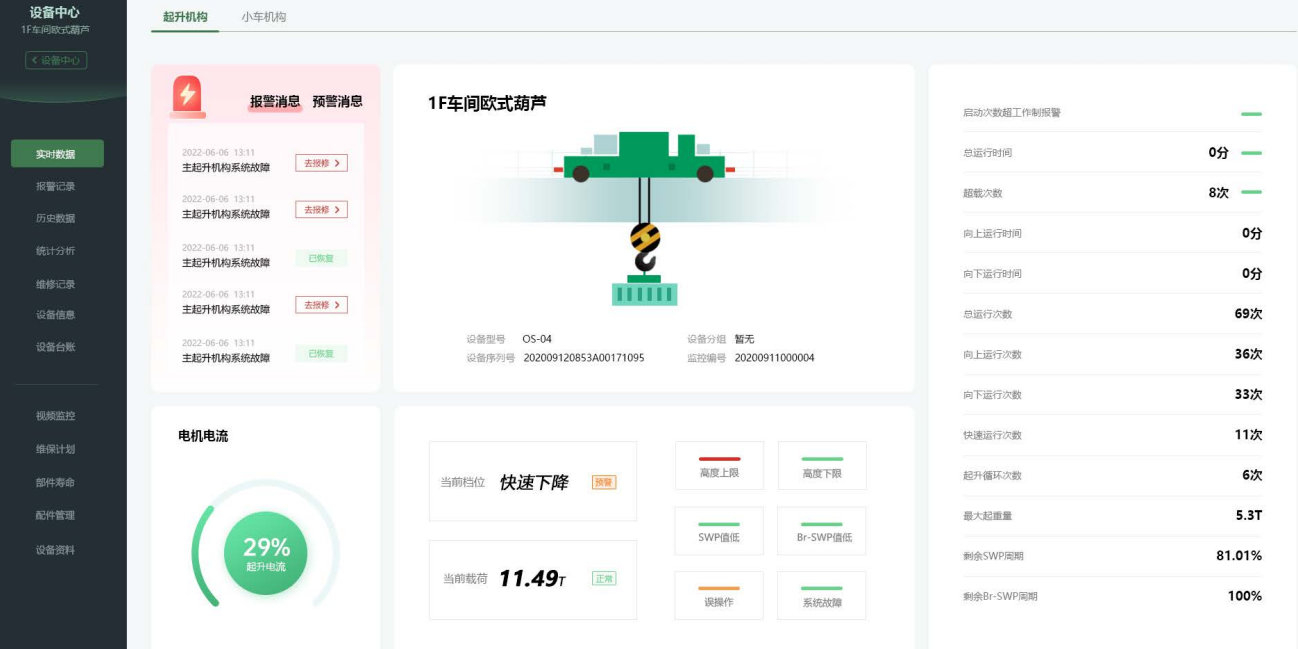

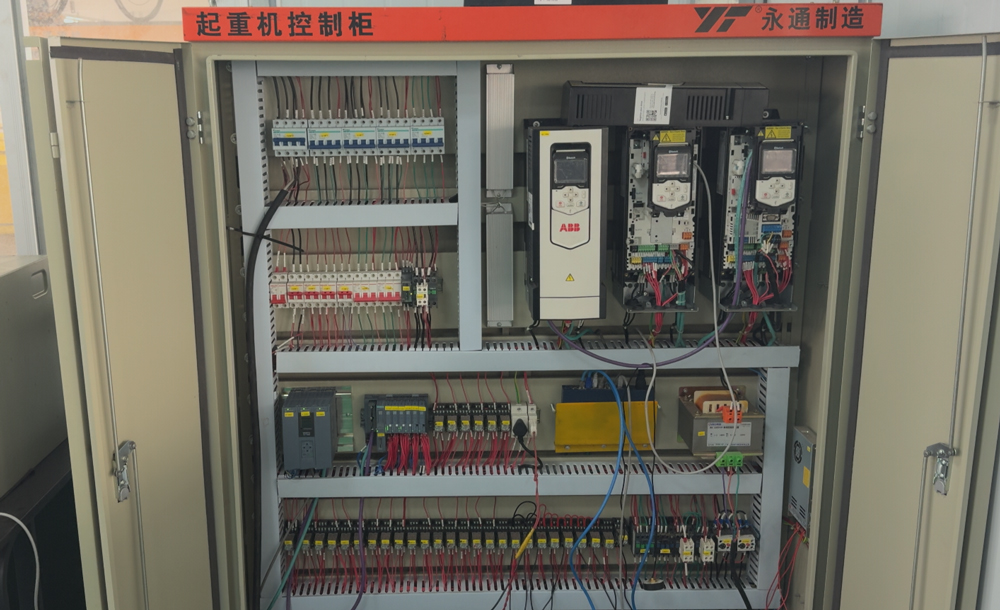

Crane remote monitoring system is a kind of bridge crane remote monitoring and operation system used in metallurgy, iron and steel, logistics and transportation industry factory workshop, aiming to realize the user to bridge crane equipment equipment data acquisition. Here we take an in-depth look at the key components and functions of Yongtong Crane remote safety monitoring system:

Centralized control of multiple cranes: Through the crane intelligent management system, you can centrally control the operating status of multiple cranes. This helps improve productivity and optimize staffing.

Sensor system: The sensor can sense various parameters in the operation of the crane, such as weight, alarm, operation times, etc., and transmit these data to the monitoring center. By monitoring the sensor data in real time, the abnormal situation of the crane can be found in time, and corresponding measures can be taken to ensure its safe operation.

Remote operating system: The system is responsible for reading and writing the data of the data collector on the console, and displays the key signals, running trend graphs, and fault alarm information.

Alarm system: Alarm system is an important part of the crane safety monitoring system. When the monitoring center receives the abnormal alarm information of the crane, it will send the alarm information to the relevant personnel in a timely manner through the sound and light alarm, SMS notification, email notification, etc., to remind them to take measures to deal with possible dangerous situations.

Maintenance data recording and analysis: The system can regularly record and store the monitoring data of the crane, and carry out data analysis and report generation. Through the analysis of the data, we can understand the operating state and work efficiency of the crane, and provide a valuable reference for the subsequent optimization and improvement.

Copyright @ Guangdong Yongtong Crane Machinery Co., Ltd. 粤ICP备2022051937号